Sensor-based activity recognition for load carriers in logistics supply chains using machine learning and artificial intelligence

Project Background

There are more than 650 million Euro pallets in circulation in Europe, and around 100 million are produced each year. Despite their industrial significance, data on the location and condition of pallets and the goods they carry is usually only collected sporadically using sensors. Continuously tracking logistical activities such as 'Driving', 'Lifting' or 'Handling' along their life cycle is hardly possible, even though the technical requirements can already be met by smart load carriers. Due to the lack of analysis regarding the process steps, optimization potential by the gain in transparency remains unexploited.

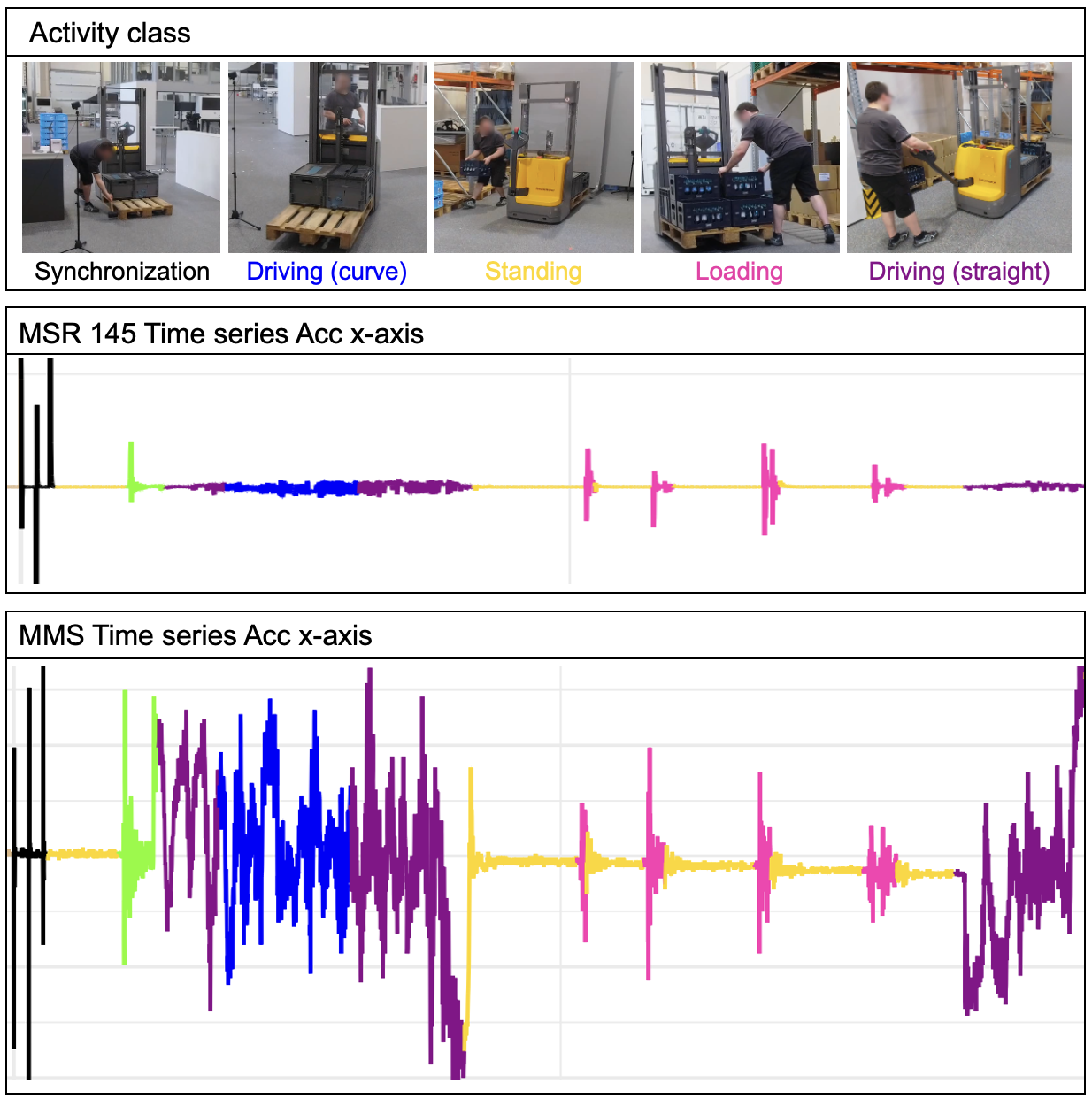

Example of operative warehouse activities and its prediction by sensors

Approach for Activity Recognition

The Pal2Rec research project conducted a feasibility study which showed that logistical activities can be recognized through the use of sensor technology and AI. The first data sets were recorded under laboratory conditions and published as the Sensor-based Pallet Activity Recognition in Logistics (SPARL) data set. In addition, an initial taxonomy of activities was developed.

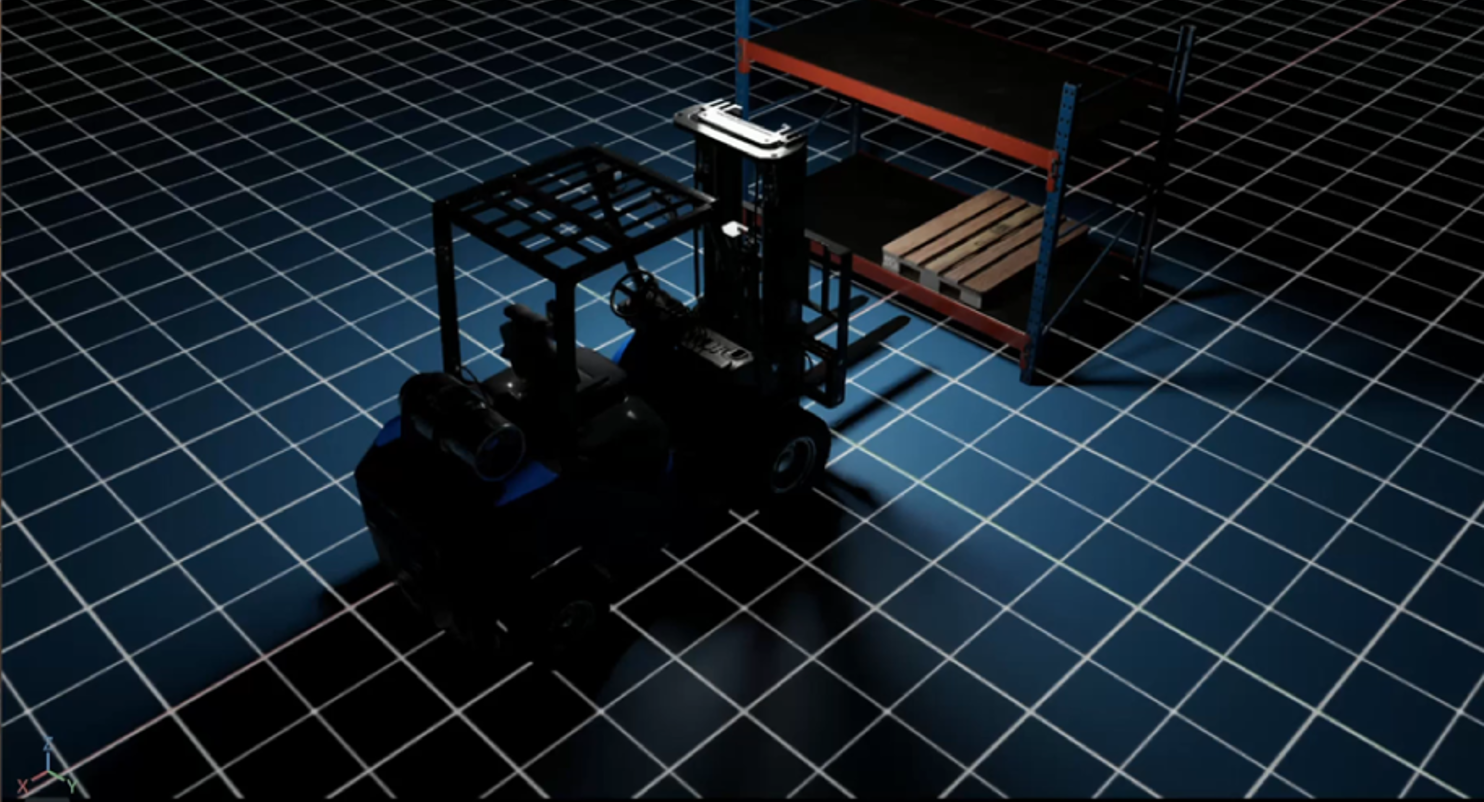

While Pal2Rec provided a taxonomy and a first dataset to prove feasibility, the subsequent Lamarr Project Pal2Sim addresses the key challenge of model robustness. The high variability of logistical influences — such as vehicle types, loading scenarios, and process flows — result in a need to have a very large and diverse set of training data. To deal with this and the needed effort of collecting the data, Pal2Sim pursues the approach of generating synthetic sensor data using physical simulation.

The aim is to examine the extent to which this artificially generated data can close the gap in real data sets and thus enable the comprehensive detection of logistics activities. Real data was recorded in an industrial partner's warehouse and identical process steps were mapped in the simulation. The data sets created expand the series of SPARL data sets. Pal2Sim's outcomes aim to enable new approaches to data-driven logistics and process optimization in supply chains.

From Real Data to Synthetic Simulation

Bridging the gap between real sensor measurements and simulated environments

Real Data

Real DataActual sensor measurements from pallets in logistics environments

Synthetic Data

Synthetic DataComputer-generated simulation environments for model training

Example of a time series and corresponding activity recognition

Developed sensor box for data acquisition